Seurat Technologies

Seurat has built the only 3D metal printing process that can compete with the volumes, quality, and price points as traditional manufacturing. Seurat’s technology will help offset carbon emissions and is helping the world achieve net-zero emissions by 2050.

Area Printing Explained

Co-Directed this video with Clum Creative (Cleveland, OH) to demonstrate how Seurat’s patented brand of Additive Manufacturing—Area Printing—is revolutionizing the way just about any metal component is made. This also includes my voice over.

Tradeshow Booth Design

Seurat's inaugural trade show presence at FormNext Austin 2023. Responsibilities included booth design, booth construction, logistics, and multimedia experience within booth. In addition, I was responsible for producing and directing original multimedia content during the show for real-time social media and future promotional purposes.

Inside Seurat: Andy Bayramian | Chief Scientist

Director, Producer, and DP example for "Inside Seurat" employee spotlight series. This is one of several shorts in this recruitment project that focused on folks who make Seurat not just a pioneering tech company, but a work-culture beacon of change for the Boston area. Seurat was chosen by The Boston Globe as a "Top Place to Work" in 2022 and 2023.

Inside Seurat: Rising Stars

Another Director, Producer, and DP example for "Inside Seurat" employee spotlight series.

Photography

As Seurat's in-house Creative Director and Photographer from 2021-2023, I was on-site and on-assignment frequently—capturing and publishing the growth of the company first hand. Pictured here is Seurat's co-founder and CEO, James DeMuth, standing inside a soon-to-be commissioned Area Printing chamber at their Wilmington, MA headquarters in Q4 2022.

Photography

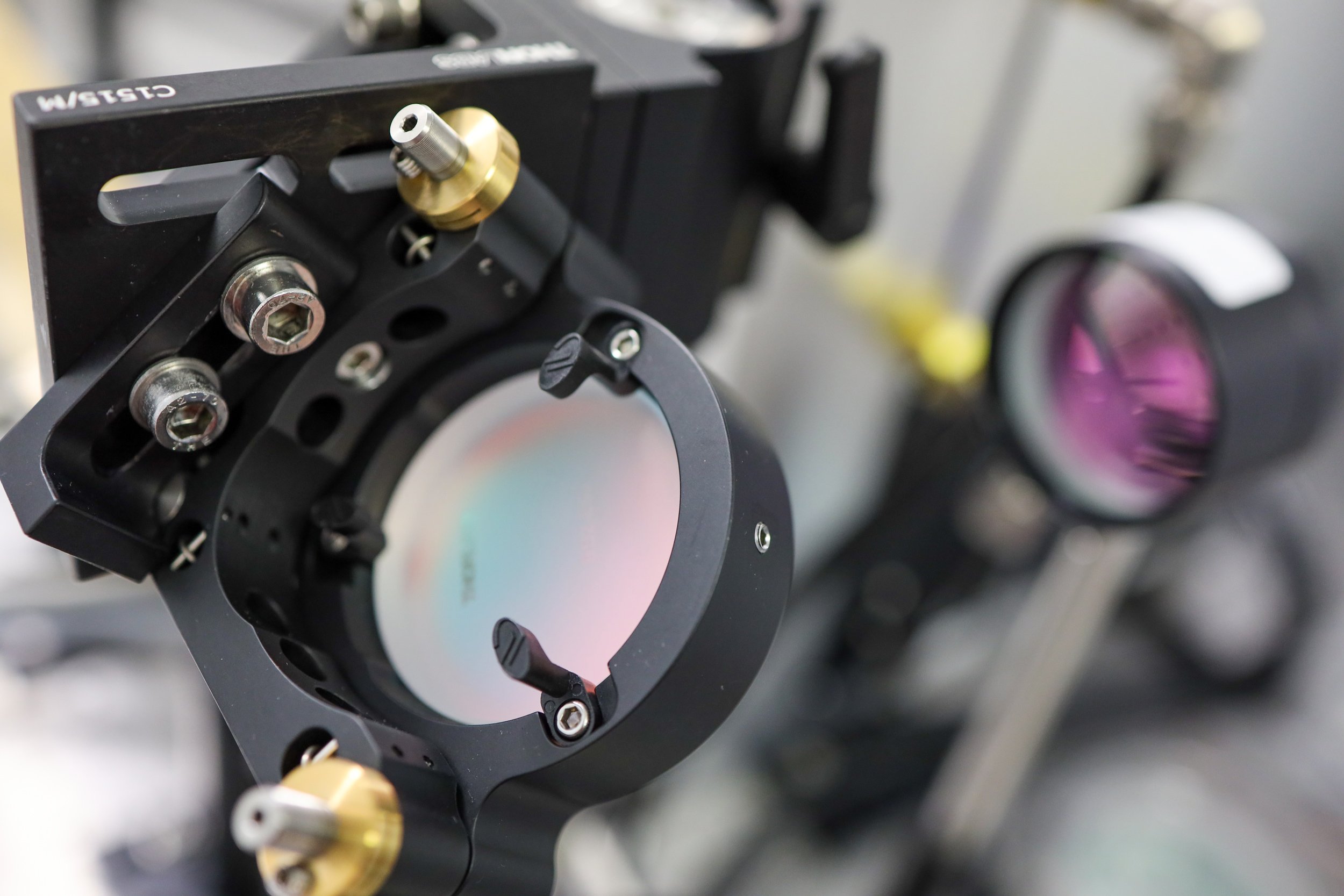

Like Georges Seurat's brush technique, Seurat Technologies applies the same basic principle to laser light and powdered materials. Unlike traditional additive manufacturing, Area Printing from Seurat uses a powerful laser containing over 2.3 million pixels—like brush strokes—to micro-weld thin metal powder layers to the area below it, manufacturing entire renderings at once in a single defined area.

Area Printing connects the dots to give the world a new perspective.

Photography

Seurat has developed and patented Area Printing, which has the potential to break through the limits of today’s metal Additive Manufacturing. Rather than increasing the number of laser sources, Seurat uses a completely new method of beam manipulation to increase melted volume per time.